Capabilities

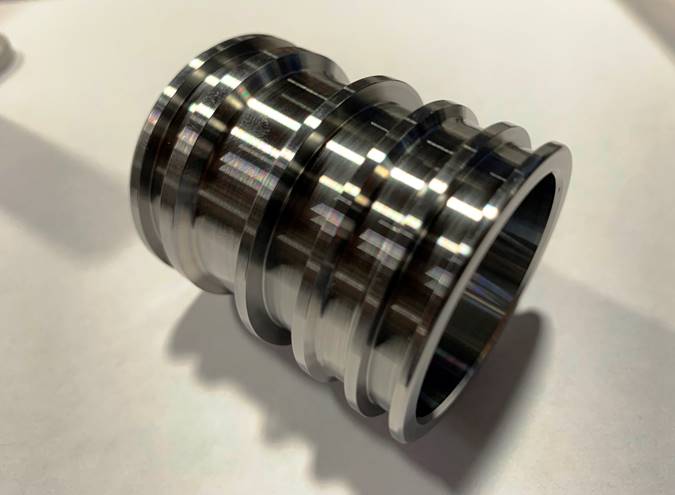

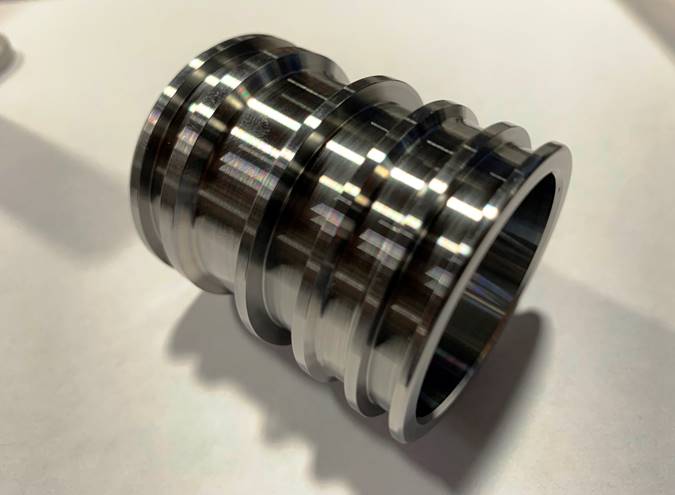

Pacific Gears specializes in CNC Milling and CNC Turning to provide customers a wide selection of innovative, precision engineered solutions in machining parts of various complex geometries. Our climate controlled shop floor helps us to achieve greater precision and maintain accuracies to the last micron. With a capacity of over 80,000 machining hours/year and ever expanding, our facilities are equipped with state-of-the-art machines run with latest tooling and CAD/CAM programs.

We have expertise and extensive experience in working with exotic materials like Inconel, Hastelloy, Titanium, Radio Metal and Duplex Steels, titanium, and Aluminum Alloys. Our teams of skilled CNC machinists look forward to challenges and different levels of jobs complexity is achieved with unparalleled quality and precision to provide accurate parts each and every time.

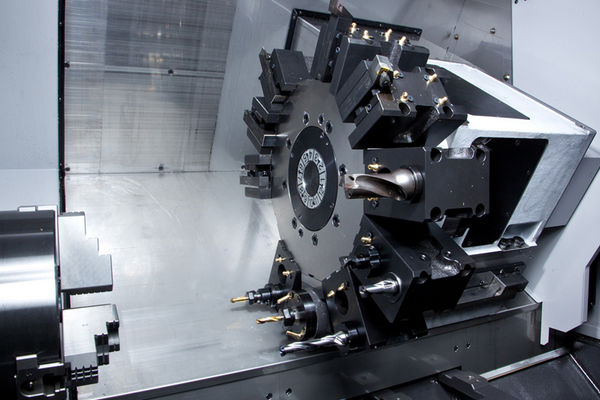

CNC Turning:

We have a host of Tsugami make CNC machines turning out parts in thousands with exact dimensions. We also have Swiss type Automatic lathe that can machine parts from 3mm to 20mm in diameter and can offer up to 7 -axis capabilities. We can help a wide range of customers by delivering both small and large quantities with very less lead times and competitive prices.

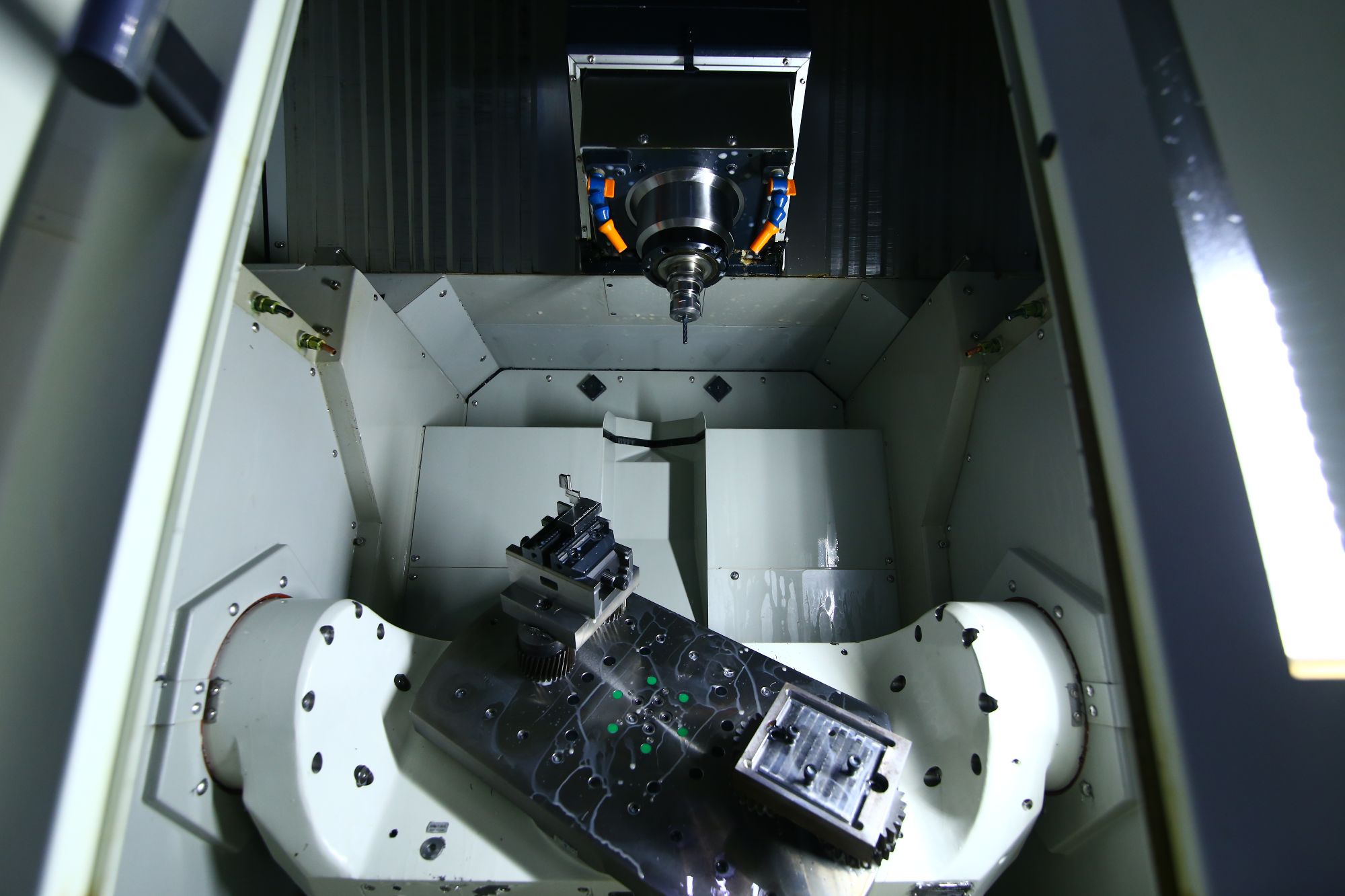

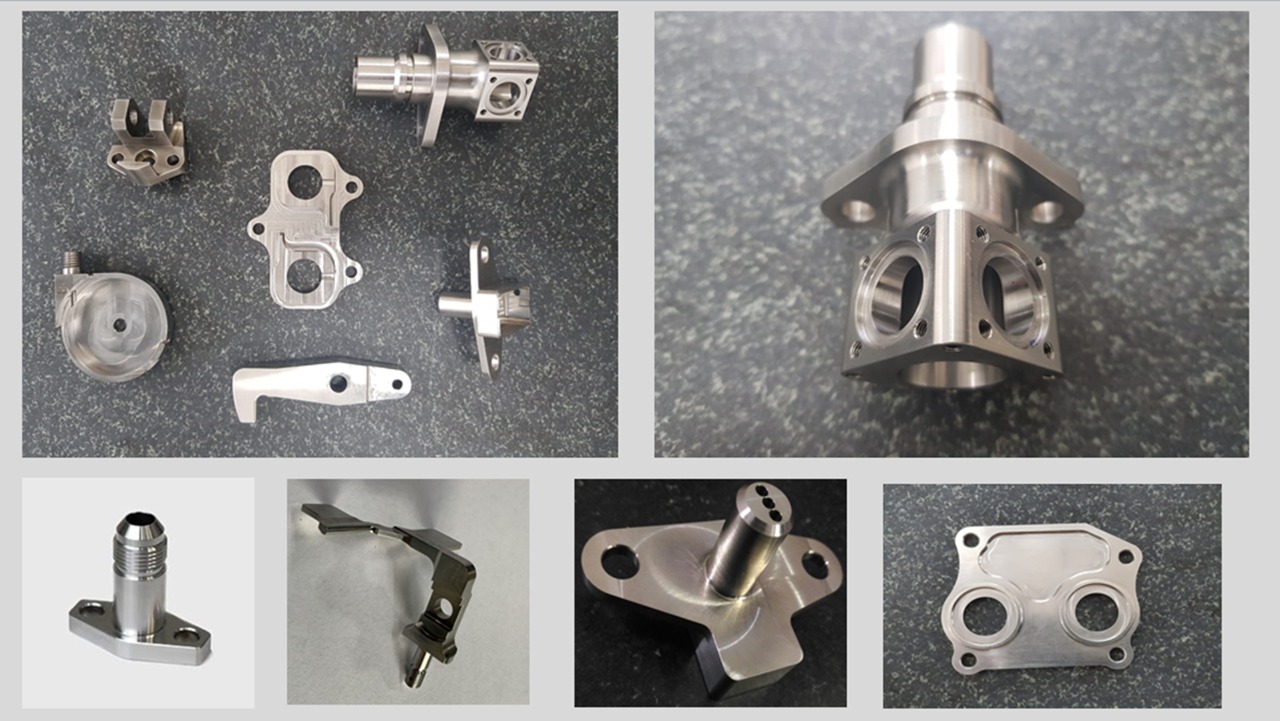

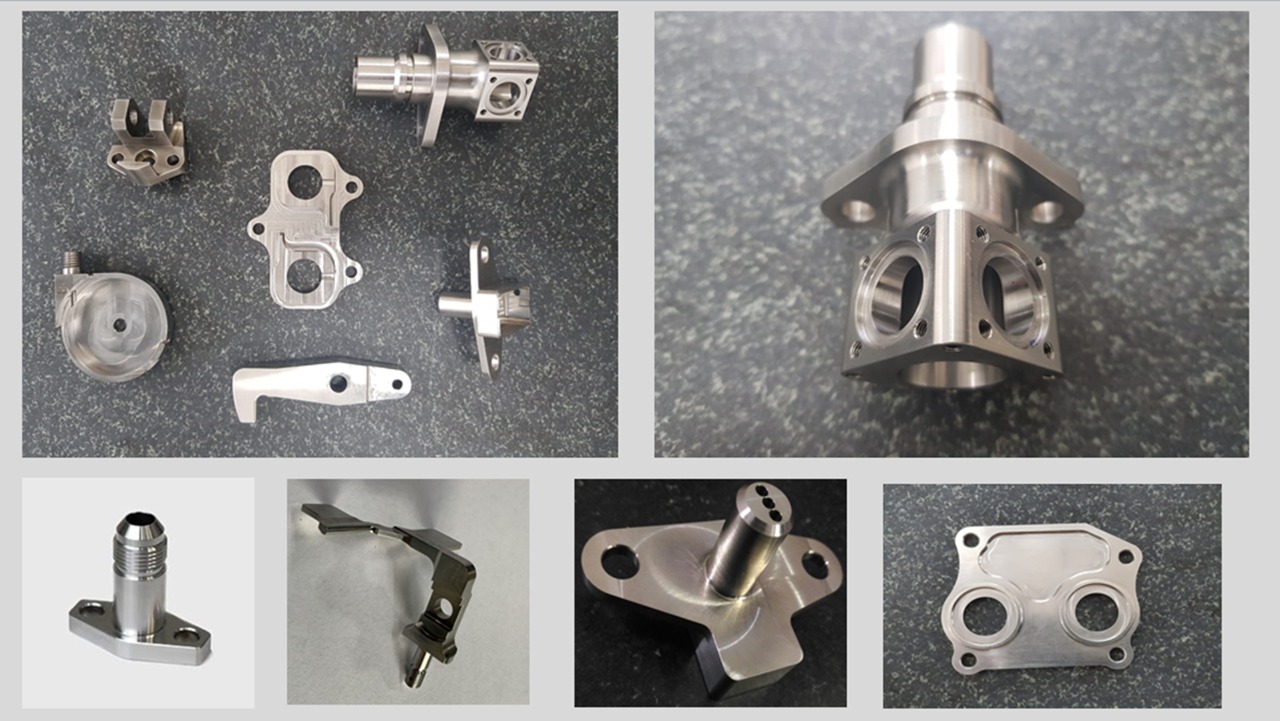

CNC Milling:

Our CNC milling facility in conjunction with a large number of Makino make Machining Centres with 4th and 5th Axis positioning capabilities is something that we pride upon. We are always ready to take on challenges in very complex shapes, materials and accuracies that most people envy.

We specialize in small part sizes up to 12 inches cube and can flawlessly process using cutting edge technologies in Tooling and Quality Control.

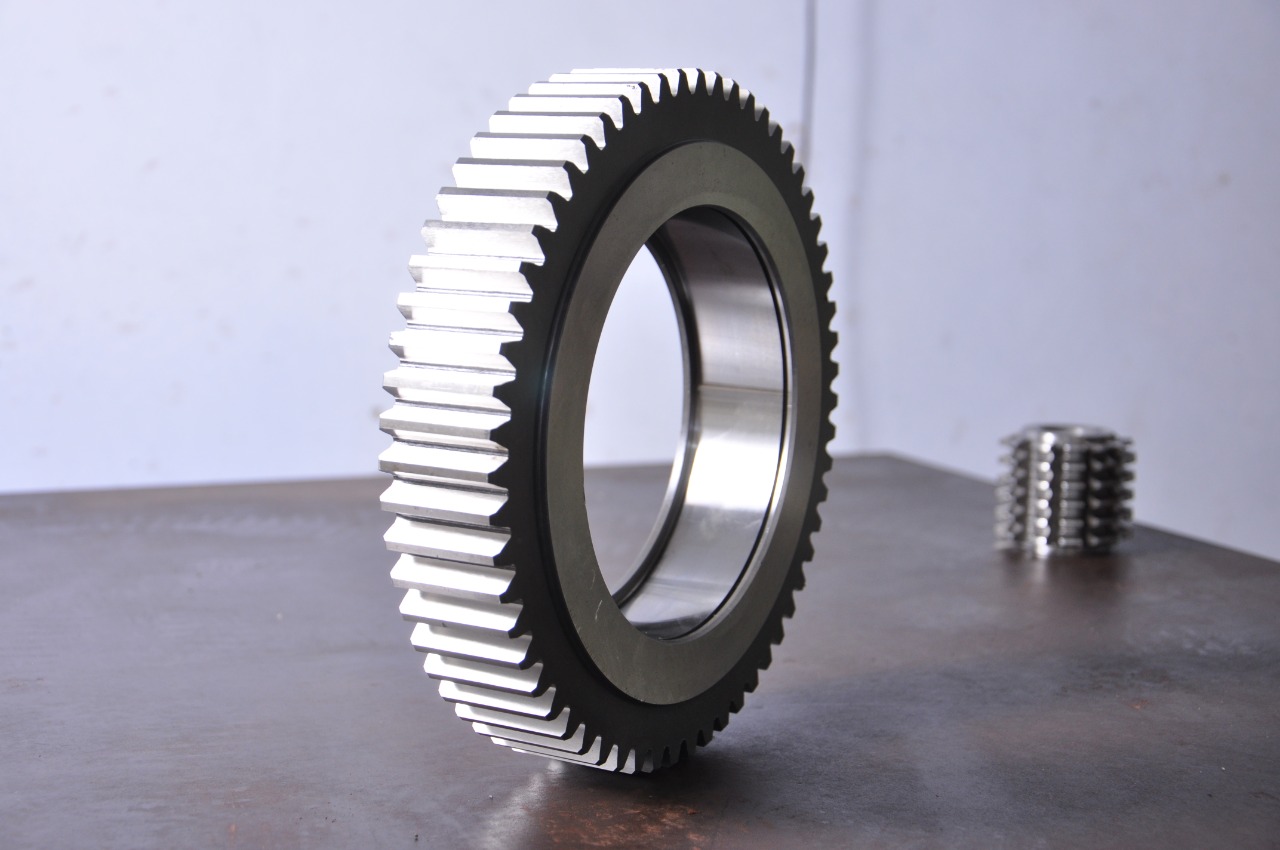

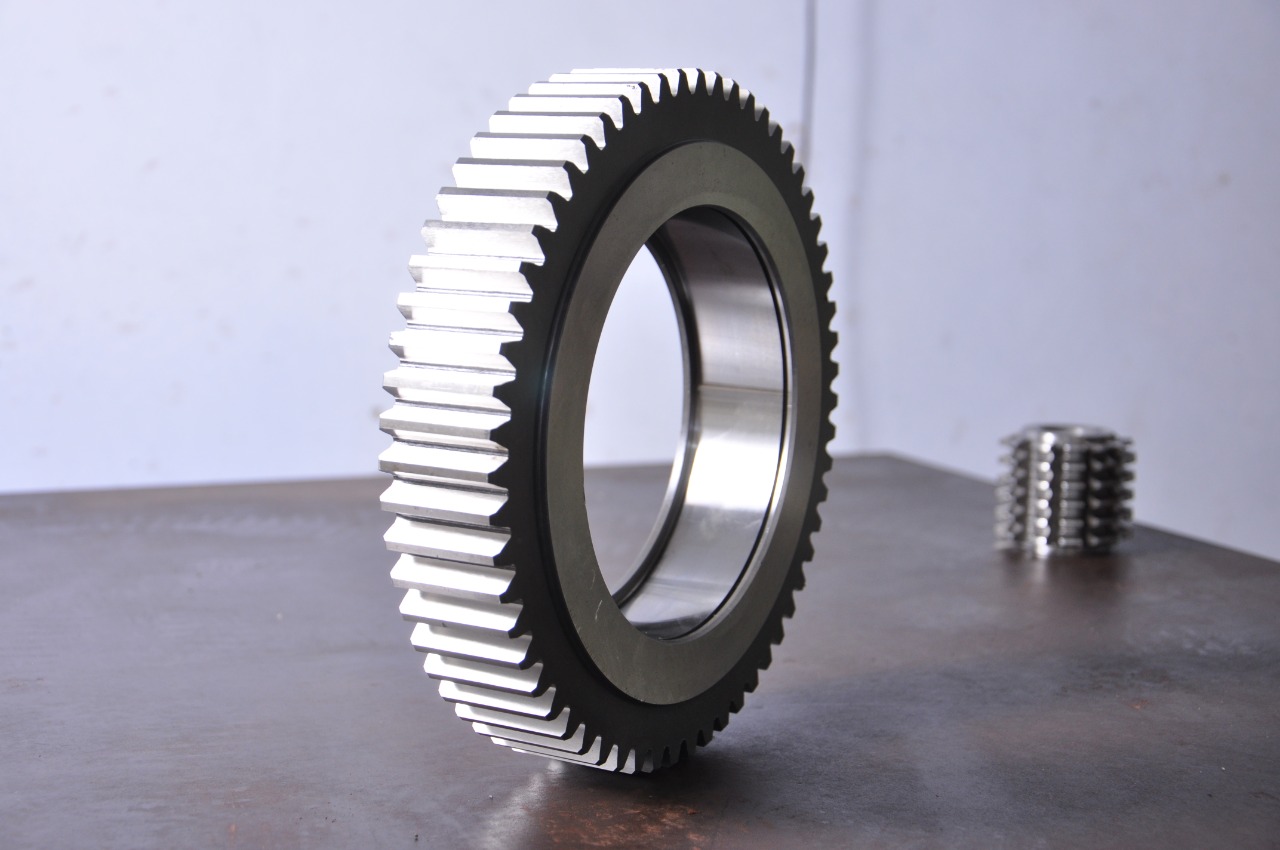

Gear Hobbing and Grinding and Conventional Machining:

We offer to manufacture gears to exacting DIN standards up to 12 modules and 350mm Diameter.

Our skilled and experienced machinists have not forgotten the art of conventional machining and still produce accurate parts on a day to day basis.

We also have a host of conventional machinery like Surface Grinders, Drill Presses, Lathes etc

At Pacific Gears we lay a lot of focus on quality assurance (ISO 9001 : 2015) and highly efficient manufacturing procedures. Our hard earned reputation is gained over the years by providing accurate delivery of cost effective production and competitive lead times.